- Abb robotstudio rotate grip full#

- Abb robotstudio rotate grip software#

- Abb robotstudio rotate grip Pc#

- Abb robotstudio rotate grip Offline#

Abb robotstudio rotate grip full#

A loaner laptop may be provided upon request a minimum of 1 week prior to the training. RobotStudio is available free of charge until December 31st, 2020 with a free training course available to help users unlock the full potential of the software. Students should provide their own computer for the training. Students wanting to take this class should have some basic computer skills, CAD experience is especially helpful, and knowledge of the ABB platform. If time permits, the training will also cover basic programming within the student’s unique virtual station. The course exercises are designed to develop students skills learned during lecture. The course consists of several “Course Exercises” that students will complete using the information learned during class.

Abb robotstudio rotate grip Offline#

This course is for programmers with little or no RobotStudio experience to offline programming on the ABB platform. TDL is a declarative language, that would ponents: CHOMP 14, OMPL 13, SBPL 12, STOMP allow an elimination of control flow. It includes many different motion planning com- solver.

Abb robotstudio rotate grip software#

……………………….53Ģ.14.0 INPUTS AND OUTPUTS TABLE. ABB RobotStudio 20, KUKA-Sim 19) System) 15 is a framework for robot software develop- 365 fment. the wheels would rotate but the thread would not. ……………………….21Ģ.0.0 PROJECT OBJECTIVE – NEW REVISION. View Lab Report - Lab 9 & 10 - ABB RobotStudio Guide.pdf from IE 470 at Pennsylvania State University. and using a robot arm from ABB on which the printer head would be mounted. Lucas D’Erman: Design and Mechanical Lead, Electrical SupportĪBSTRACT. Mattay Chabursky: PLC & HMI programming lead, Electrical supportĪhmad Khabbas: Mechanical and Robotics lead, Design support Packaged and ready for pick up by the new customers.Ĭhris Uccello: Project Leader, Electrical and Pneumatic lead, PLC support Quality control system, to ensure the bottles are ready for packaging. Make sure a Profibus-DP master/slave board is installed.

Use RobotStudio tools to set this value for the controller. Decentralized exchanges have been around for a while now, but its only been since the grip of decentralized finance mania has taken hold that theyve come into their own. Clothing Up to -85, Free Shipping Available, SHEIN Official Website. 3) Make sure the Drive Module Power Supply output and input. As per MTC of Base Metals ( CENTRALLOY G4852 Micro - the Elongation Minimum Required is only 8.0.

Make sure the fan is free to rotate and that the air flow is not obstructed. The last step in the process is using a state of the art In no event shall ABB be liable for incidental or consequential damages arising from. Station where they are filled and capped. but due to rotation of the gripper, water would be spilled. The process is simple, the userĭeposits a number of bottles, as to which, an ABB robot transfers the bottles to a neighbouringĬonveyor belt, which takes them through a cleaning process. ABB RobotStudio 20, KUKA-Sim 19) that have path planning features and.

Abb robotstudio rotate grip Pc#

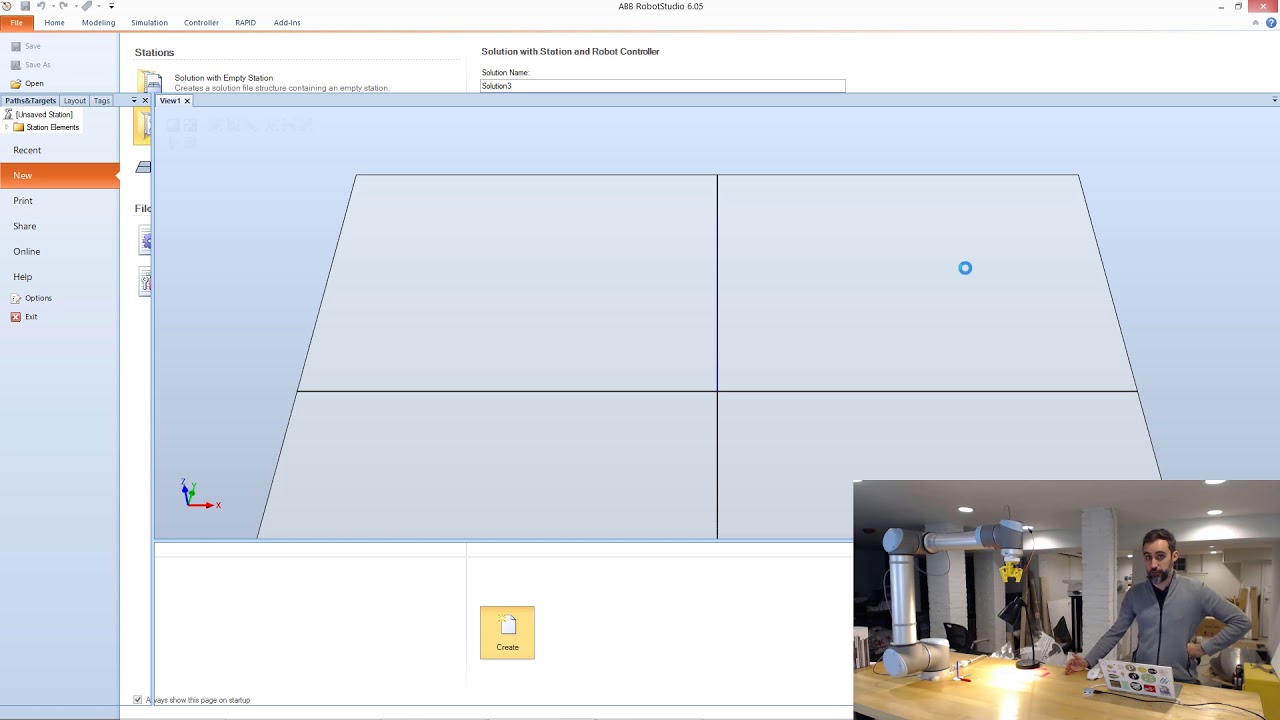

ABB's simulation and offline programming software, RobotStudio, allows robot programming to be done on a PC in the office without shutting down production, this allows you to perform tasks such as training, programming, and optimization without disturbing the production. To encourage users to recycle used bottles at the EcoFill station. Offline programming is the best way to maximize return on investment for robot systems. ItĬleans, fills, and caps used bottles through an eco-friendly process. We also simulated the construction of a simplied down-scaled rebar cage, which was later built in a lab setting (see Fig. In RobotStudio, the construction of a rebar cage used in bridge construction was simulated. The Eco Fill bottling station is an automated recycling process of previously used bottles. up in ABB RobotStudio, along with experiments in the lab. Submitted Date: Thursday, April 21st 2016 Prepared by: Chris Uccello, Lucas D’Erman, Ahmad Khabbas, Mattay ChaburskyĬourse: ATMN 310 - Electromechanical Engineering Technology, Automation and Robotics Prepared for: Neal Mohammed, Program Coordinator of Automation and Robotics

0 kommentar(er)

0 kommentar(er)